Electric powertrain solutions

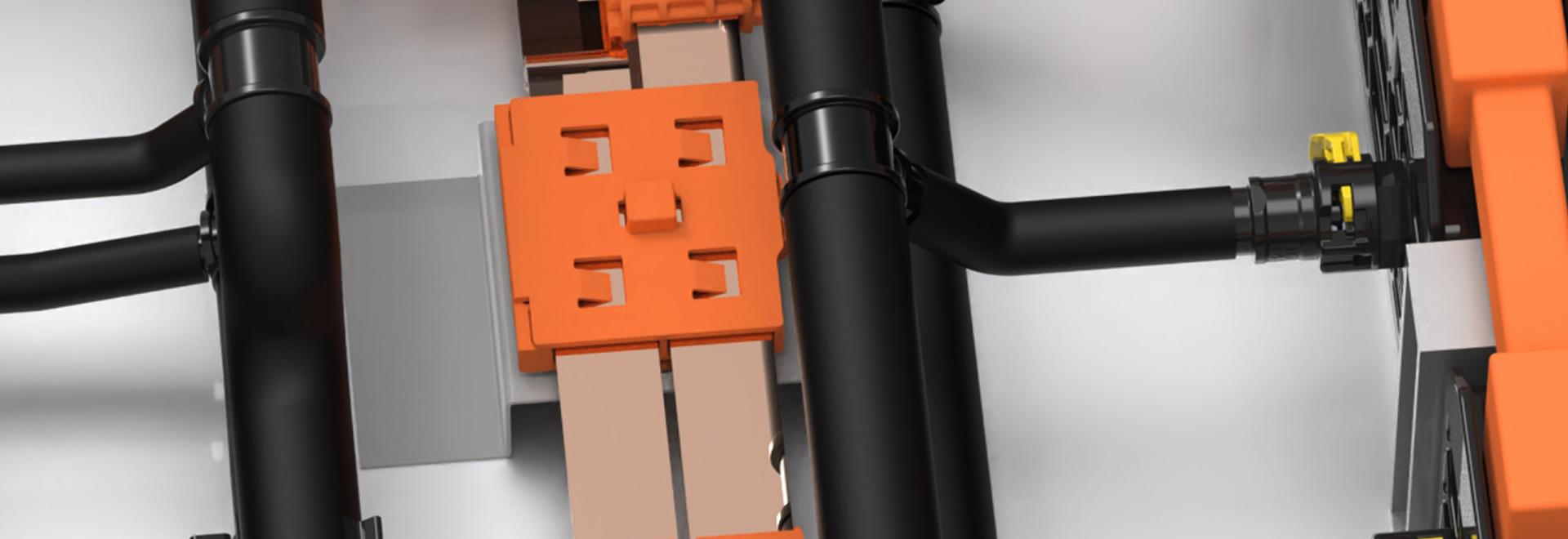

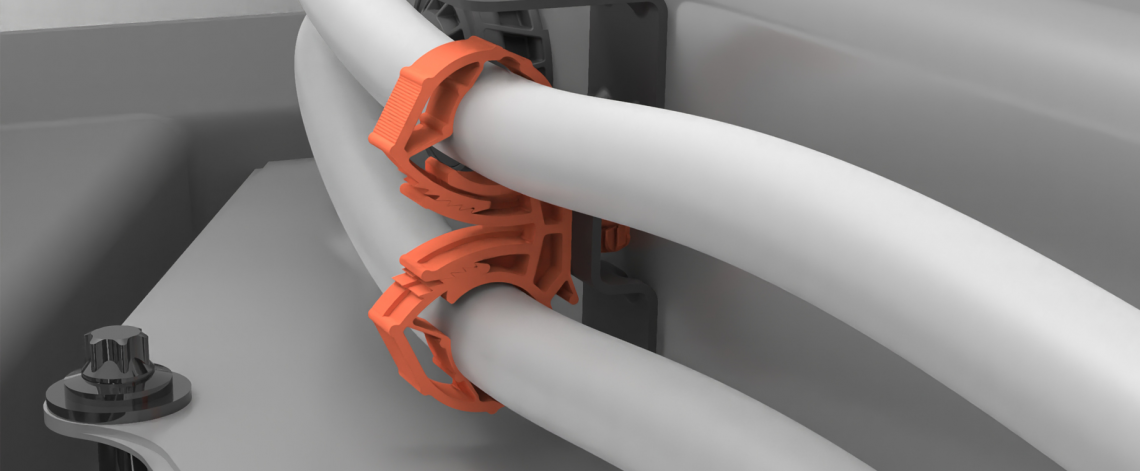

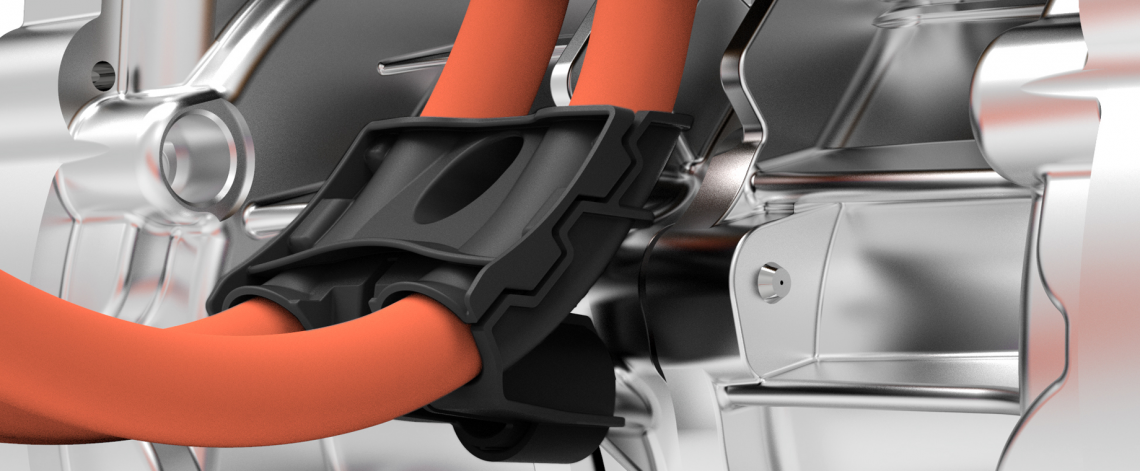

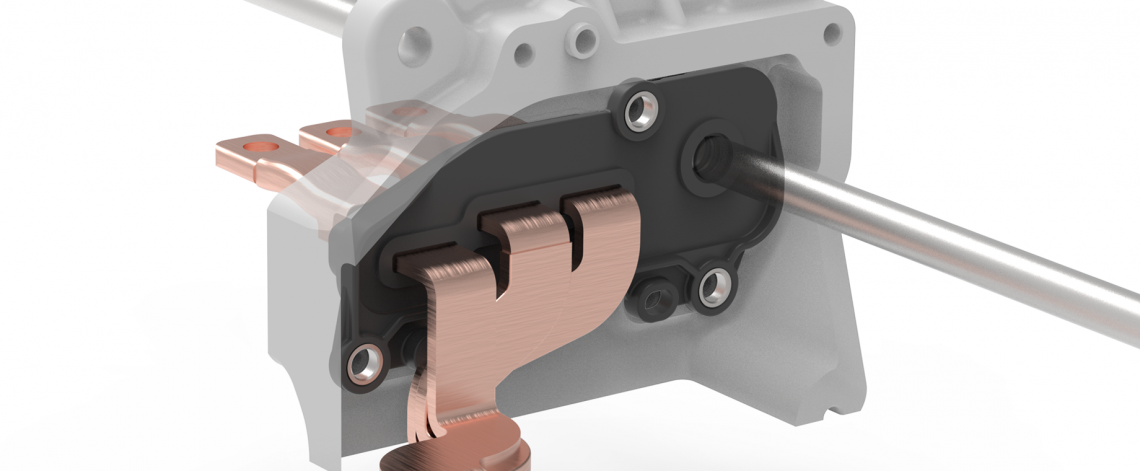

We partner with OEMs and automotive equipment suppliers to simplify EV system architectures and deliver the benefits we are known for: ergonomic and secure assembly processes for a safe, high-quality assembly that lasts as long as the vehicle.

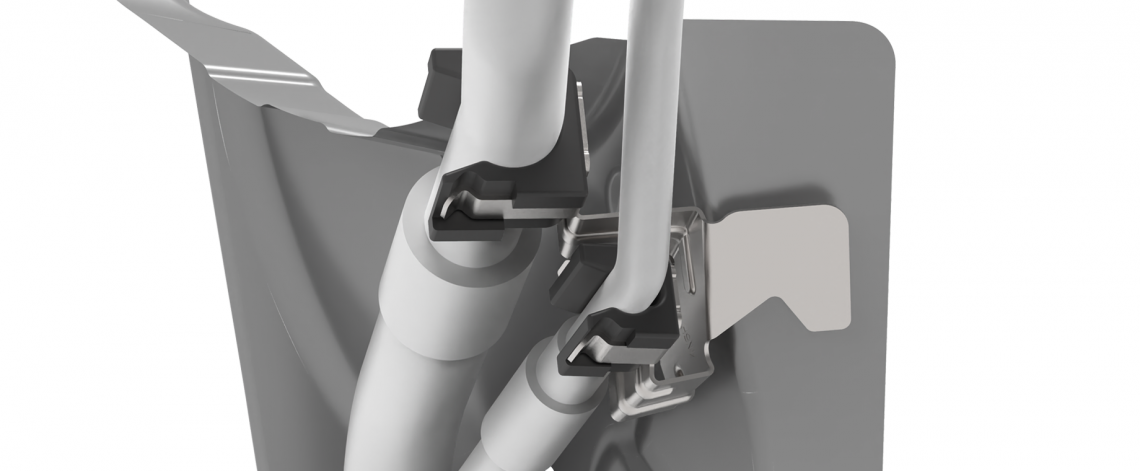

High Voltage Routing for Electric Vehicles