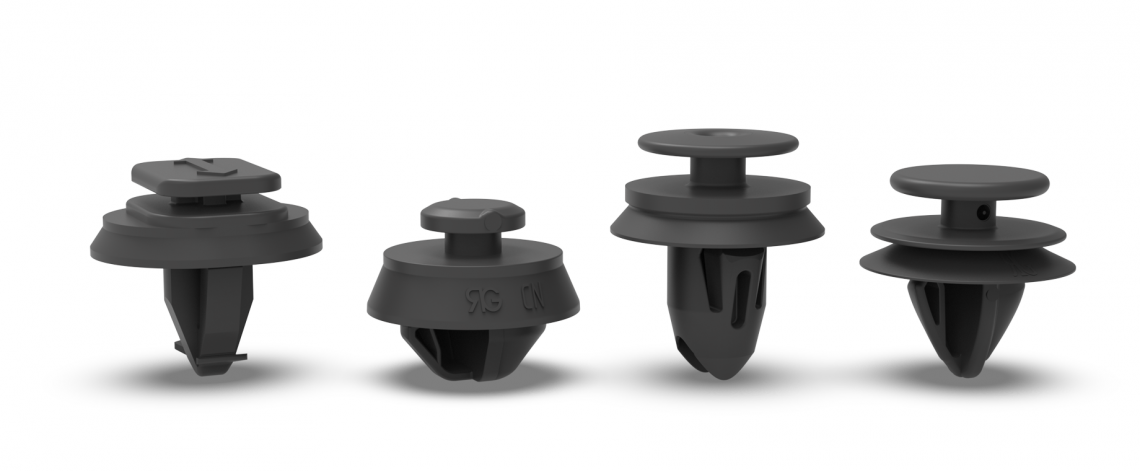

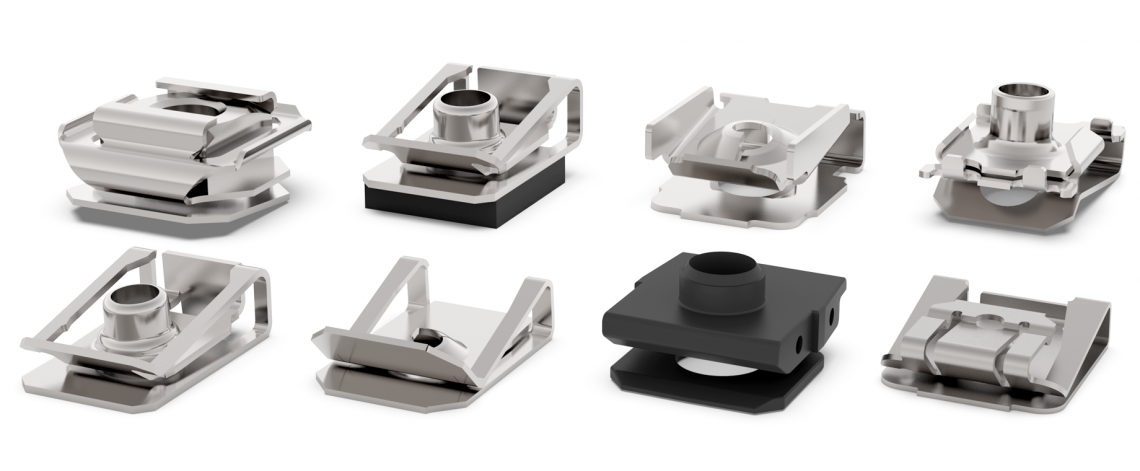

ARaymond panel fasteners are all-in-one parts that eliminate the need for additional fasteners or complex assembly operations.

Our screwless solutions are easy to assemble and are available to accommodate most panel orientations and sizes. Our snap-fit panel fasteners are quick to assemble and invisible once mounted.

We can manufacture parts from metal for reduced vibration and noise or plastic for greater cost-effectiveness and corrosion resistance.

Versatile threaded fasteners

Our threaded fasteners combine the dependability of common threaded fasteners and the versatility of spring steel to offer value-added solutions that can be used in most assembly environments. ARaymond nuts are lightweight and easy to assemble. Our wide range of standard products can accommodate most panel orientations and sizes, fit several panel thicknesses, and are suitable for both metric or self-tapping and PT thread screws.