At ARaymond, we provide an unparalleled selection of Quick Connectors to our customers.

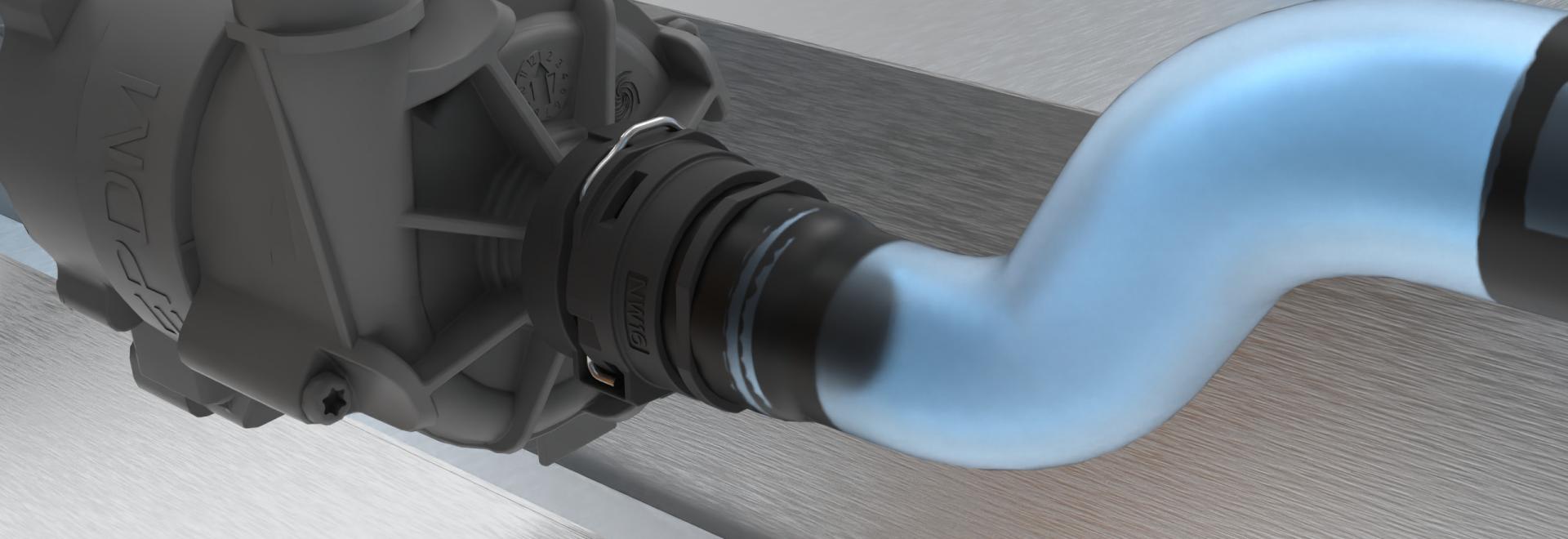

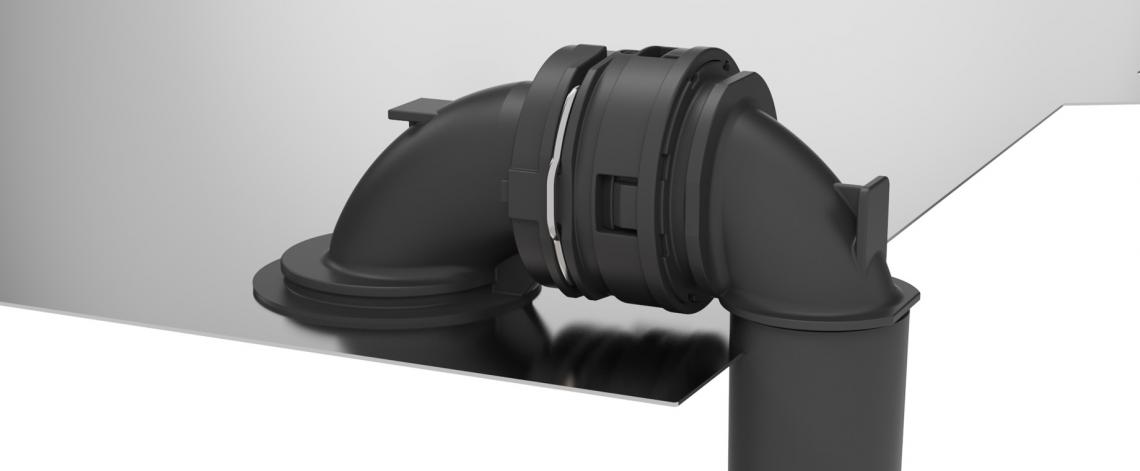

Our top-of-the-line assembly solutions guarantee reliable and efficient performance for a variety of automotive fluid lines, ranging from fuel systems to EV thermal management.

Our Quick Connectors are both durable and ergonomic, allowing for easy and secure connections without the use of tools. With a diverse range of diameters and designs available, utilizing Quick Connectors can significantly reduce assembly cycle time, conserve space and weight, and simplify serviceability.

Quick connectors for fluid lines